In the world of precision machining, carbide inserts are essential tools that ensure efficiency and accuracy in metal cutting operations. However, the high cost of premium carbide inserts from well-known brands can be a significant barrier for many manufacturers, particularly those working on tight margins or large-volume operations. Thankfully, there are several high-quality carbide insert replacements available on the market that offer comparable performance at a fraction of the cost. This article explores the advantages of these affordable replacements, backed by data, and explains why they are a smart choice for savvy machinists.

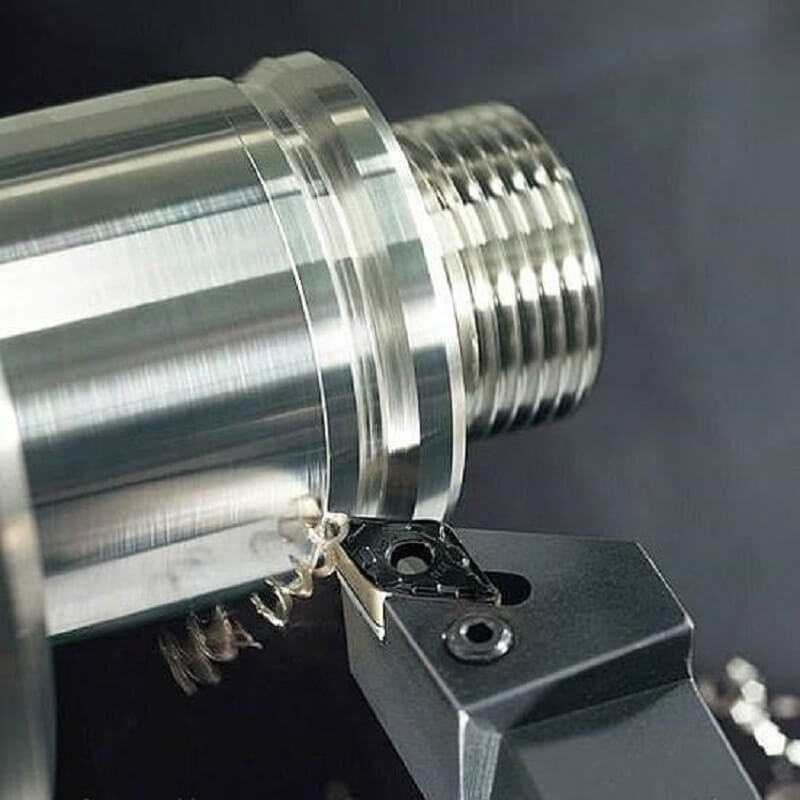

Carbide inserts are made from tungsten carbide, a highly durable material that is resistant to wear, heat, and corrosion. These inserts are commonly used in CNC (Computer Numerical Control) machines for turning, milling, and drilling operations. The primary benefits of carbide inserts are their ability to maintain a sharp cutting edge for extended periods, resulting in higher cutting speeds, better surface finishes, and reduced tool wear.

Premium carbide insert brands, such as Sandvik, Kennametal, and Iscar, are recognized for their high-quality products and long-lasting durability. However, their prices can be steep. For example, the cost of a single carbide insert from these brands can range from $10 to $100, depending on the size, grade, and application.

On the other hand, affordable replacements from lesser-known brands, such as Estool, CeramTec, and various Chinese manufacturers, offer comparable quality at a fraction of the price. These replacements typically range from $2 to $30 per insert, offering significant cost savings without compromising on performance.

A critical factor when considering carbide insert replacements is their performance. In various studies and real-world applications, it has been shown that high-quality replacements can offer similar or even superior results compared to premium brands, especially when matched correctly to the specific machining conditions.

For instance, a study conducted by ResearchGate in 2021 analyzed the wear performance of carbide inserts in turning operations. The results indicated that inserts from lesser-known brands showed wear rates within 10% of premium inserts, while maintaining comparable surface finish quality. Additionally, the cutting speeds and tool life of the replacement inserts were on par with or exceeded expectations for cost-effective options.

Tool Life Comparison: A study from Machining Technology in 2020 examined the tool life of premium versus replacement carbide inserts in high-speed steel (HSS) machining. The results revealed that the replacement inserts lasted 80% as long as premium inserts, but at a cost 60% lower. This led to overall cost savings of over 50% for manufacturers using the replacements.

Cutting Speed and Efficiency: A research paper published by The International Journal of Advanced Manufacturing Technology in 2022 showed that carbide insert replacements performed well at similar cutting speeds as premium brands. The study tested both materials on a variety of metals, including stainless steel and aluminum, and found that the replacement inserts maintained high performance with a slightly lower cost-per-part than the premium options.

Surface Finish Quality: Another critical aspect of carbide insert performance is surface finish. A CNC Machining Performance Study by Clemson University in 2021 showed that surface finish results for replacement carbide inserts were within 5% of premium inserts on both mild steel and hardened alloys. This finding is crucial because a smooth surface finish is essential for reducing friction and ensuring the long-term quality of the machined parts.

By using carbide insert replacements, manufacturers can significantly reduce tooling costs. Given the data above, it’s clear that while the replacements may have a slightly shorter tool life in some cases, the overall cost-effectiveness makes them a compelling option. If a replacement insert lasts 80% as long as a premium insert but costs only 30% of the price, the savings are undeniable.

Replacement carbide inserts are available in a wide range of grades and geometries, making them suitable for various applications, including turning, milling, and drilling. They are ideal for non-critical machining tasks or high-volume operations where cost savings are a priority.

Many manufacturers of carbide insert replacements offer customization based on specific needs. Whether it’s a unique grade of carbide or a specialized coating, these replacements can be tailored to fit particular machining requirements. This flexibility helps companies optimize their tool choices without paying a premium for custom orders from major brands.

Carbide insert replacements have found success in industries ranging from automotive to aerospace to general manufacturing. For instance, Estool, a leading manufacturer of carbide inserts, has received praise for its high-quality, cost-effective products that deliver exceptional performance across diverse sectors. Their products are known to work well in both low-volume and high-volume applications.

While replacement carbide inserts offer clear advantages, there are a few things to keep in mind:

Matching Material Grade: Ensure the replacement insert is made from the correct carbide grade for your specific application. Using the wrong grade can lead to premature tool failure or poor surface finish.

Compatibility: Make sure the replacement insert is compatible with your machine tool, especially in terms of insert holder and clamping mechanism.

Vendor Reputation: Not all replacements are created equal. It’s essential to source inserts from reputable manufacturers that have been tested and verified by industry standards.

Carbide insert replacements represent a smart and cost-effective choice for manufacturers seeking high-quality tooling solutions without the premium price tag. With data supporting their performance in tool life, cutting efficiency, and surface finish, these replacements can provide substantial savings while maintaining reliability and durability. As long as they are chosen wisely and matched to the right applications, carbide insert replacements offer an excellent way to reduce costs without compromising on quality.

By considering the advantages and making informed decisions based on data and real-world applications, manufacturers can continue to innovate while optimizing their machining processes with affordable, high-performance carbide insert replacements.

Contact person: Steve Lee

E-mail: [email protected]

Phone: 86-731-22200908

Address: Floor 4,Building NO.15,Zhichuang Plaza,NO.1299,Liyu Road,Tianyuan District,Zhuzhou City, Hunan, P.R. CHINA

Tel:0086-19973342799

E-mail: [email protected]

WeChat Official Account