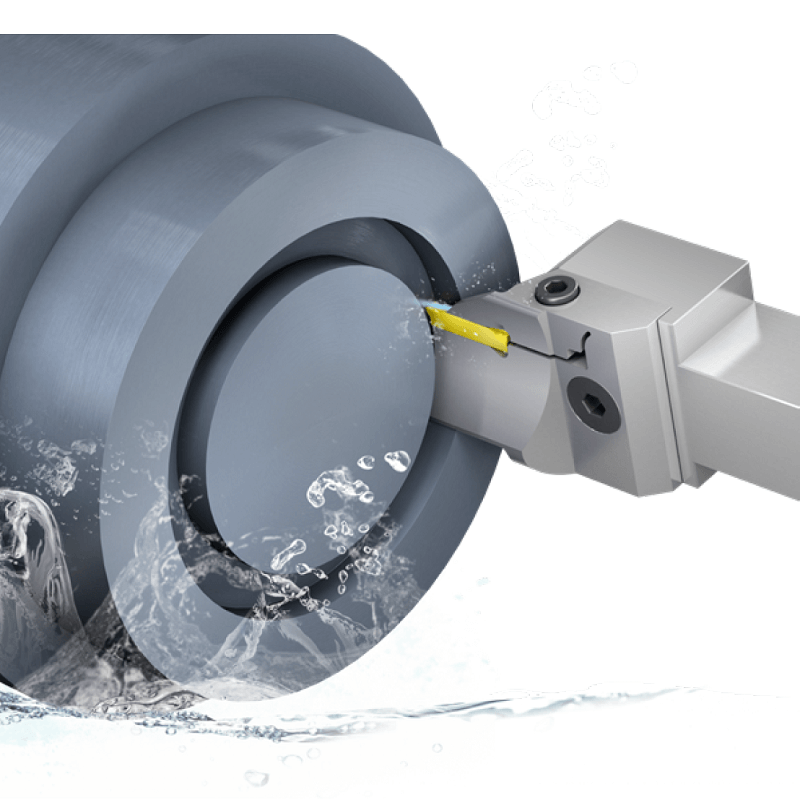

In the highly competitive and demanding field of pipe and tube production, efficiency and quality are paramount. Scarfing inserts, specialized cutting tools designed to remove surface material, play a critical role in improving both. This article explores how scarfing inserts enhance efficiency in the production of pipes and tubes, focusing on their unique advantages and contributions to the manuf...

Read more

Cermet and carbide inserts are two of the most widely used cutting tools in the machining industry. Both materials offer unique advantages and are selected based on specific application requirements. This article delves into the comparative cutting performance of cermet and carbide inserts, examining their material properties, machining capabilities, and application....

Read more

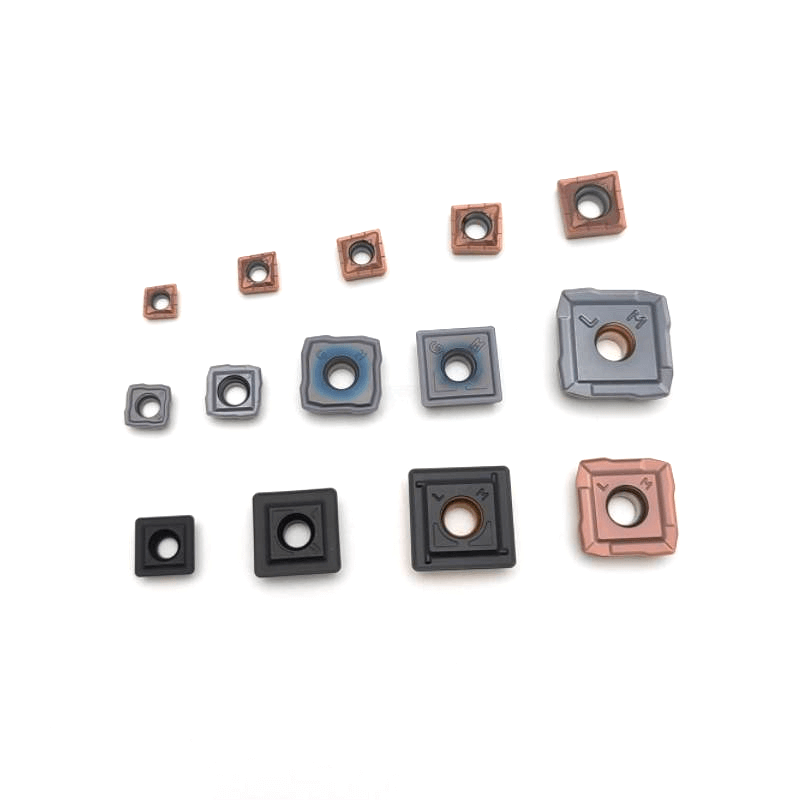

In the realm of Computer Numerical Control (CNC) machining, the design of cutting inserts plays a pivotal role in determining the efficiency, precision, and versatility of the machining process. CNC inserts, often made from carbide, ceramic, or other advanced materials, come in various shapes tailored to specific machining tasks and materials. Understanding the common shapes utilized in CNC insert...

Read more

Tungsten carbide has emerged as the material of choice for cutting tool inserts due to its exceptional hardness, strength, and wear resistance. This unique combination of properties makes tungsten carbide inserts highly desirable for a wide range of cutting and machining applications. In this article, we will discuss the various reasons why tungsten carbide is the preferred material for cutting to...

Read more

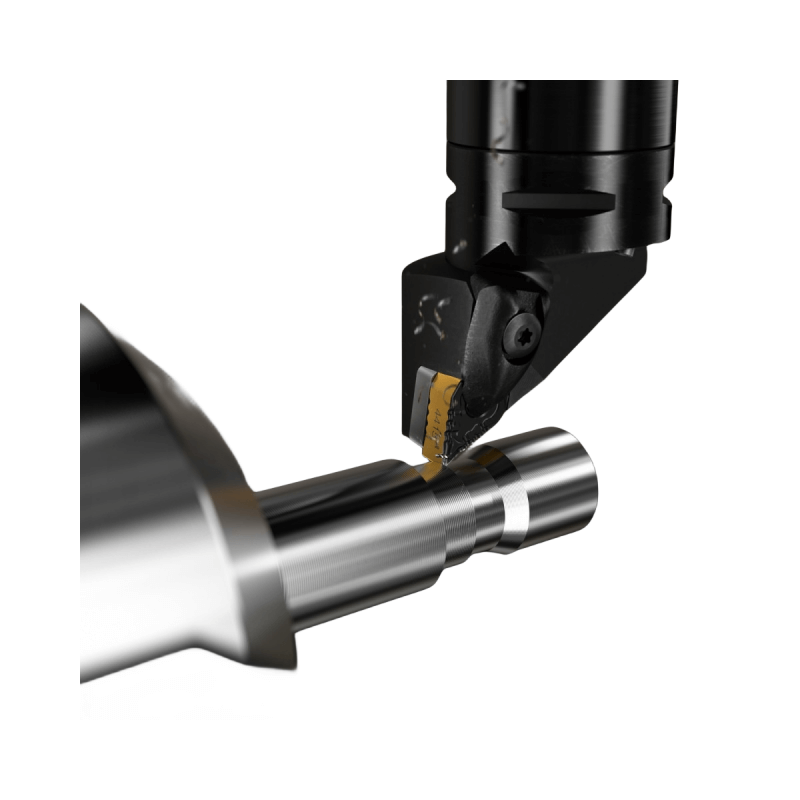

When it comes to grooving inserts for cutting tools, choosing the right one can make a significant difference in the efficiency and quality of your machining operations. Grooving inserts are used in a variety of applications, from turning and boring to threading and parting off. With so many options available on the market, it can be overwhelming to determine which grooving insert is best suited f...

Read more

Carbide inserts are widely used in various industries for cutting, milling, drilling, and shaping metal and other materials. These inserts offer several advantages that make them popular in industrial applications. This article discusses the benefits of carbide inserts in different industries and their impact on productivity, cost-efficiency, and performance....

Read more

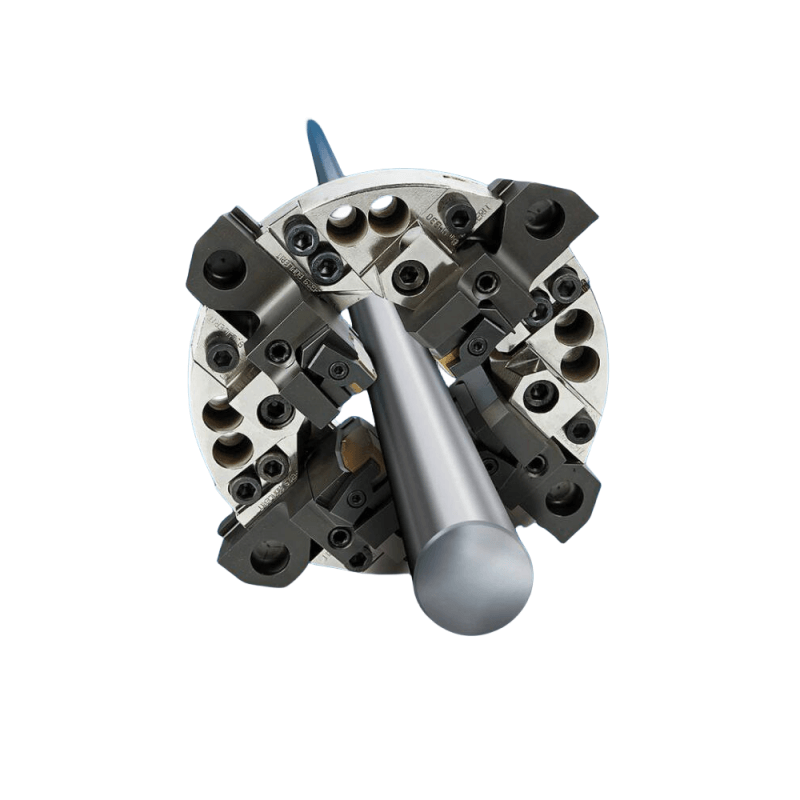

Bar peeling inserts play a crucial role in the metalworking industry, enabling efficient and high-quality machining operations. When selecting bar peeling inserts, it is essential to consider several key features that can significantly impact their performance and effectiveness. These features include material composition, coating, geometry, and overall durability....

Read more

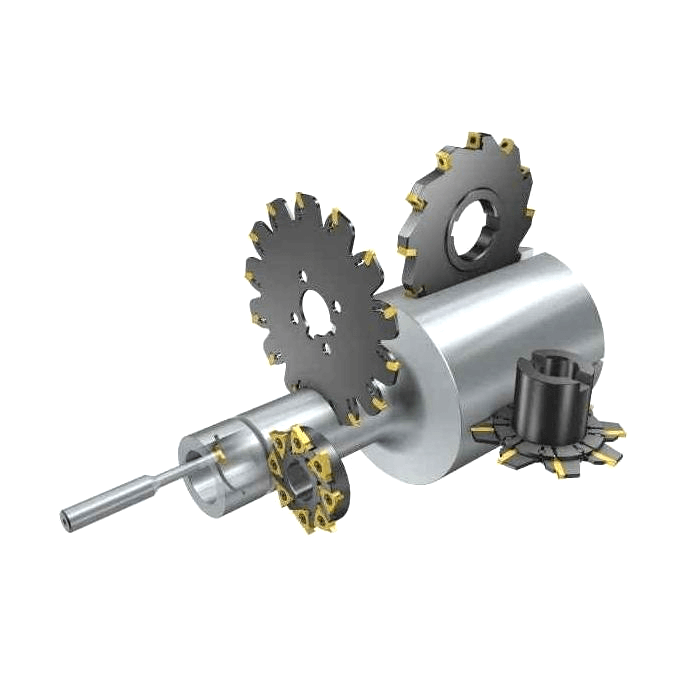

Slot milling cutters are essential tools used in the manufacturing industry for cutting and shaping materials. They are designed to create slots or grooves in workpieces, and they differ from other types of milling cutters in several key ways....

Read more

Choosing the correct coating for a carbide insert is a critical decision that directly impacts machining performance, tool life, and overall productivity. With a variety of coating options available, it is essential to consider several factors to ensure the optimal selection for specific machining applications....

Read more

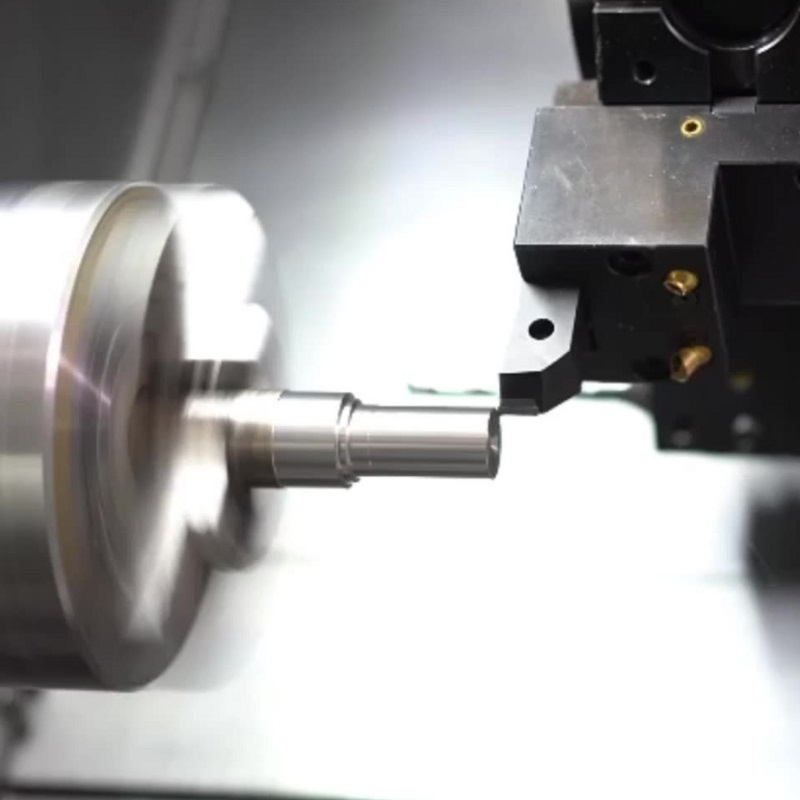

Gravity turning inserts, also known as indexable inserts, play a crucial role in the machining industry, particularly in turning operations. These inserts have been designed to address common challenges faced by cutting tools, offering a range of benefits that significantly improve machining processes. In this article, we will delve into the benefits of using gravity turning inserts and how they c...

Read moreContact person: Steve Lee

E-mail: [email protected]

Phone: 86-731-22200908

Address: Floor 4,Building NO.15,Zhichuang Plaza,NO.1299,Liyu Road,Tianyuan District,Zhuzhou City, Hunan, P.R. CHINA

Tel:0086-19973342799

E-mail: [email protected]

WeChat Official Account