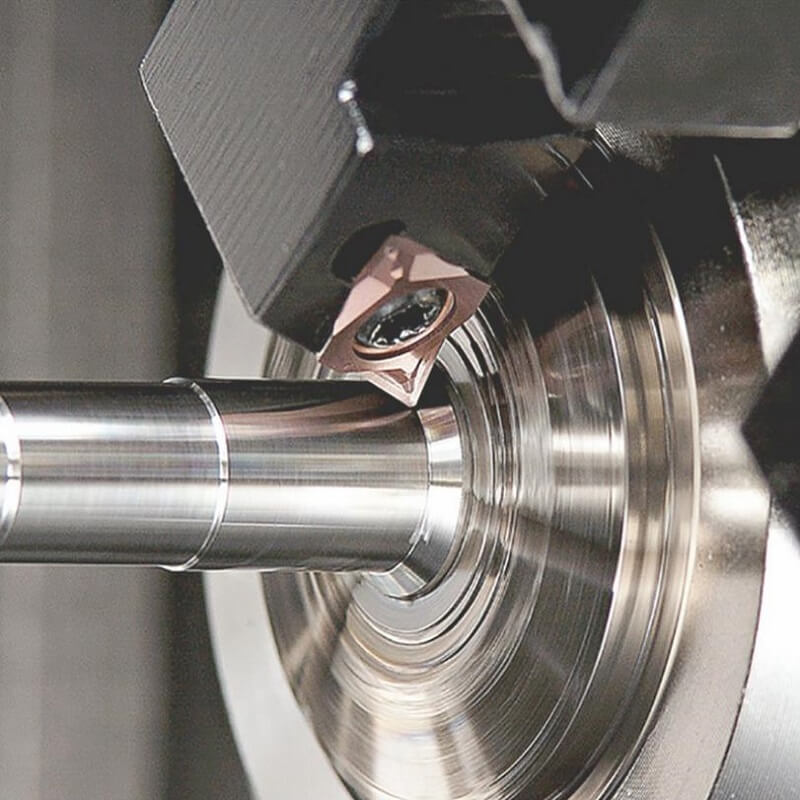

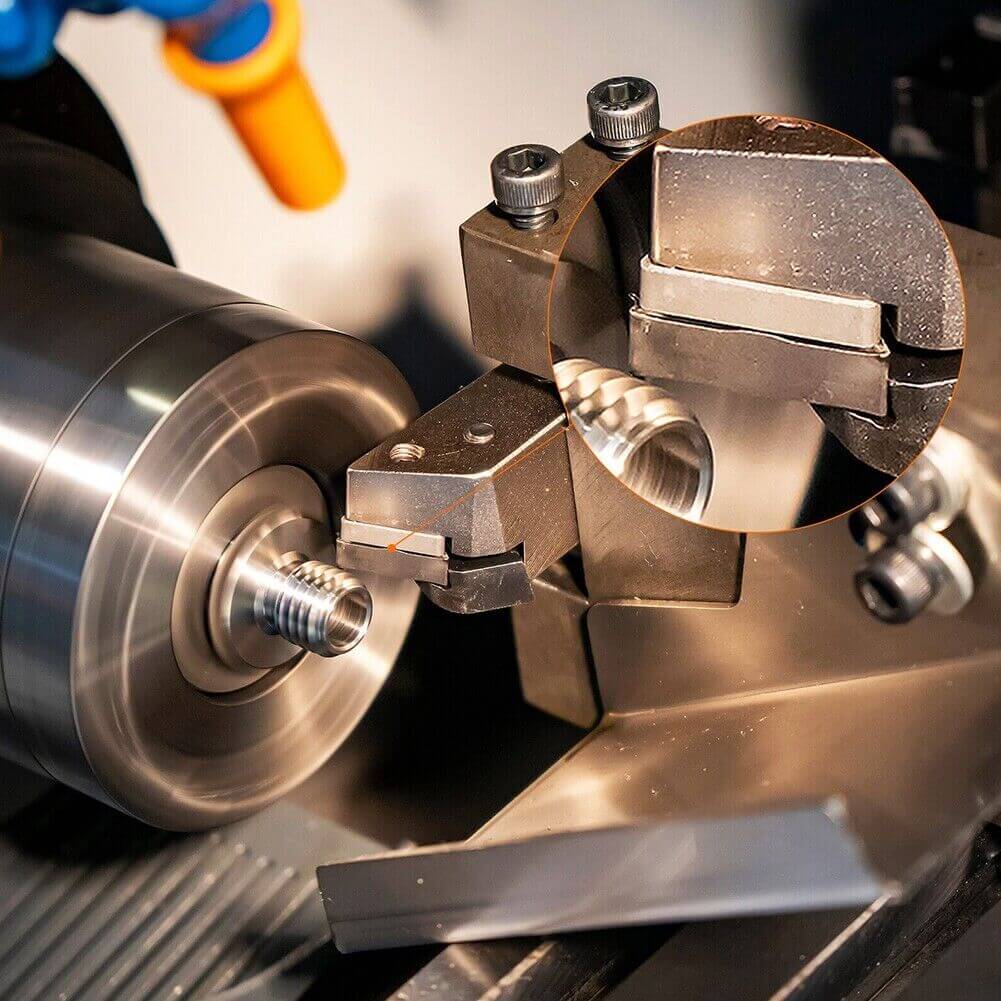

Gravity turning inserts, also known as indexable inserts, play a crucial role in the machining industry, particularly in turning operations. These inserts have been designed to address common challenges faced by cutting tools, offering a range of benefits that significantly improve machining processes. In this article, we will delve into the benefits of using gravity turning inserts and how they c...

Read more

Deep hole drilling is a specialized machining operation used to create holes with large length-to-diameter ratios. It requires specialized cutting tools known as deep hole drilling inserts. This article aims to provide an overview of common deep hole drilling inserts and their applicable ranges, highlighting their features, advantages, and suitable applications....

Read more

When it comes to carbide inserts, both Iscar and Kennametal are well-respected brands in the industry. Each company offers a range of carbide inserts that are designed to meet the demands of various machining applications. While both brands have their strengths, determining which one is better ultimately depends on the specific needs of the user....

Read more

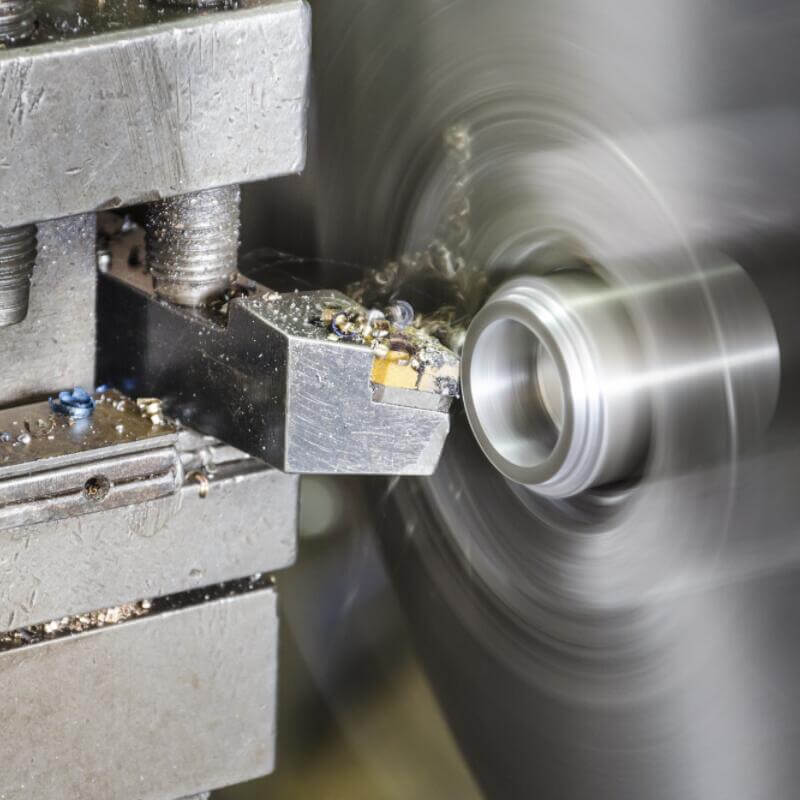

Carbide boring bars are essential tools used in precision machining processes. Carbide, known for its exceptional hardness and wear resistance, makes it an ideal material for manufacturing cutting tools. In this article, we will explore the uses and applications of carbide boring bars, highlighting their benefits and how they contribute to achieving high precision in boring and machining operation...

Read more

Turning and milling are two fundamental machining processes used in the manufacturing industry to shape and finish workpieces. While both processes involve removing material from a workpiece, they differ in their approach, tooling, applications, and cutting direction. Let's explore these differences in more detail. ...

Read more

When selecting the best CNC insert, several factors need to be considered to ensure optimal performance. These factors include the material being machined, cutting speed, feed rate, depth of cut, insert geometry, cutting edge design, and coating....

Read more

The purpose of coating carbide inserts is to enhance their performance, durability, and cutting capabilities. Coatings provide several benefits that contribute to the overall effectiveness of carbide inserts. Here are the main objectives of coating carbide inserts:...

Read more

CNC inserts play a crucial role in enhancing the efficiency and productivity of machining processes. To ensure optimal performance and longevity, it is important to take proper measures to increase the service life of CNC inserts. ...

Read more

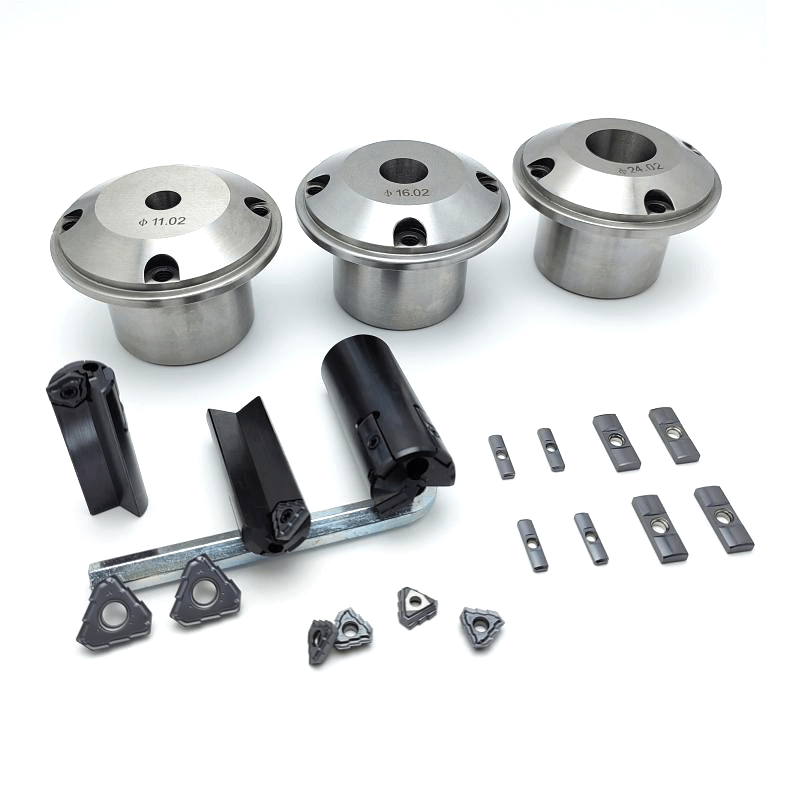

After getting the workpiece drawing, first select the indexable blade with proper shape according to the requirements of the drawing. Generally, the lathe is mainly used to turn the outer circle and inner hole, cut and cut the groove, and turn the thread. The selection of insert is determined according to the specific conditions of processing technology. Generally, the blades with high versatility...

Read more

Features of CNC machine tools: 1) Good and stable cutting performance The tool has good rigidity and high precision, and can perform high-speed cutting and powerful cutting.2) The knife has a high service life. A large number of hard alloy materials or high-performance materials are used in the knife (such as ceramic inserts, cubic boron nitride inserts, diamond composite inserts and coated inser...

Read moreContact person: Steve Lee

E-mail: [email protected]

Phone: 86-731-22200908

Address: Floor 4,Building NO.15,Zhichuang Plaza,NO.1299,Liyu Road,Tianyuan District,Zhuzhou City, Hunan, P.R. CHINA

Tel:0086-19973342799

E-mail: [email protected]

WeChat Official Account