The manufacturing world is undergoing a digital transformation. With the integration of Artificial Intelligence (AI) and Smart Machining technologies, traditional tooling components like milling inserts are evolving to meet modern machining demands. These advancements are not just about automation—they're about smarter, more adaptive, and highly optimized cutting solutions. In this article, we ex...

Read more

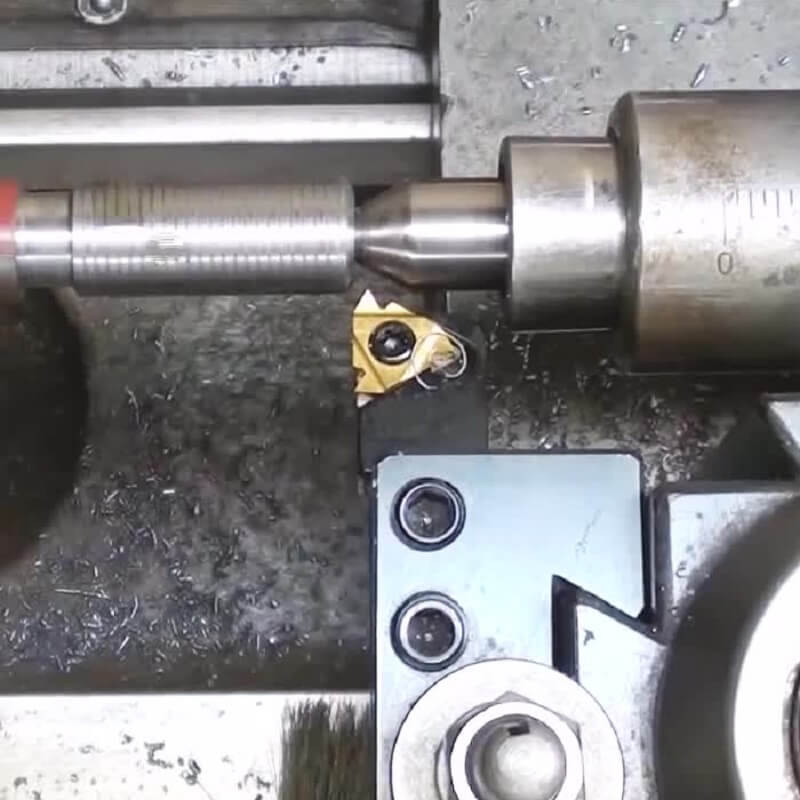

Carbide threading inserts are essential tools in modern machining processes, designed to create precise and durable threads. Among the most common types are NR, IR, and ER threading inserts. Each of these inserts serves specific purposes and offers unique benefits depending on the application. Understanding their differences can help manufacturers achieve optimal results while improving efficiency...

Read more

Aluminum machining presents unique challenges due to the material's properties, such as its softness, ductility, and tendency to adhere to cutting tools. Carbide inserts for aluminum, designed specifically for this purpose, address many of these issues, making them an indispensable tool in modern manufacturing. Below, we delve into the common problems in aluminum machining and how carbide inserts ...

Read more

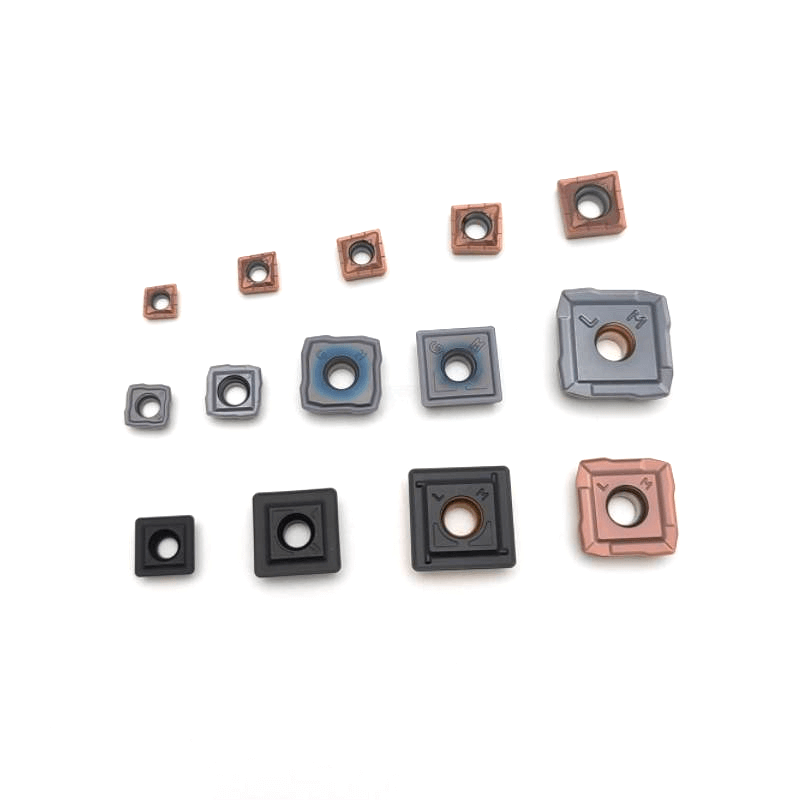

Cemented carbide inserts are widely used in various machining applications due to their exceptional hardness, wear resistance, and ability to withstand high temperatures. To maximize their lifespan and performance, proper maintenance and care are essential. This article outlines key considerations for the maintenance and care of cemented carbide inserts to ensure optimal performance and longevity...

Read more

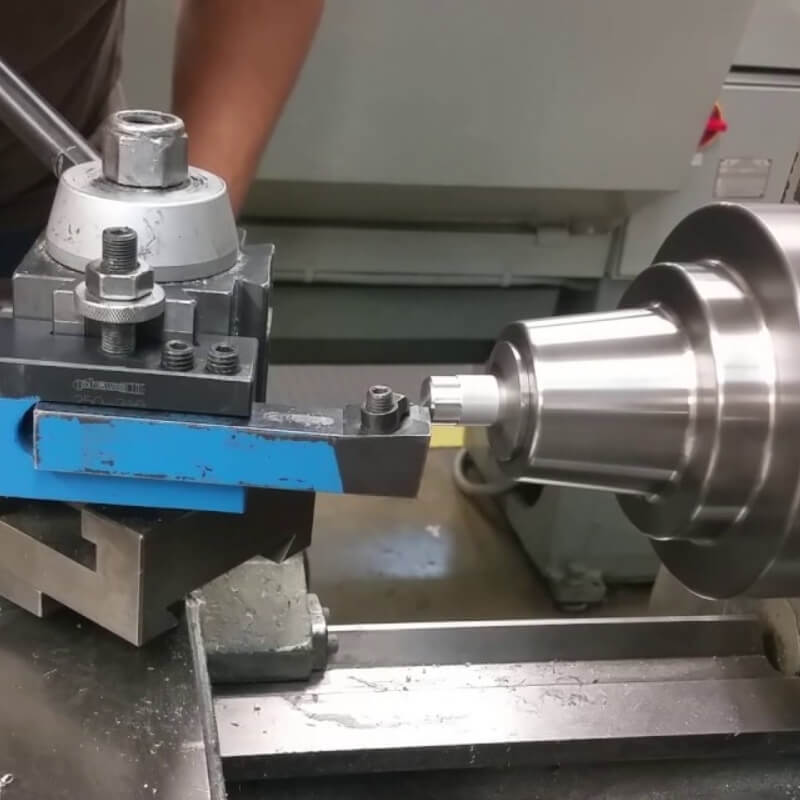

Indexable inserts are a critical component in modern machining and manufacturing, revolutionizing the way tools are utilized for cutting, shaping, and finishing materials. These inserts, also known as replaceable cutting edges, are designed to be mechanically attached to a tool holder, allowing for quick replacement without the need to replace the entire tool. This article explores the fundamenta...

Read more

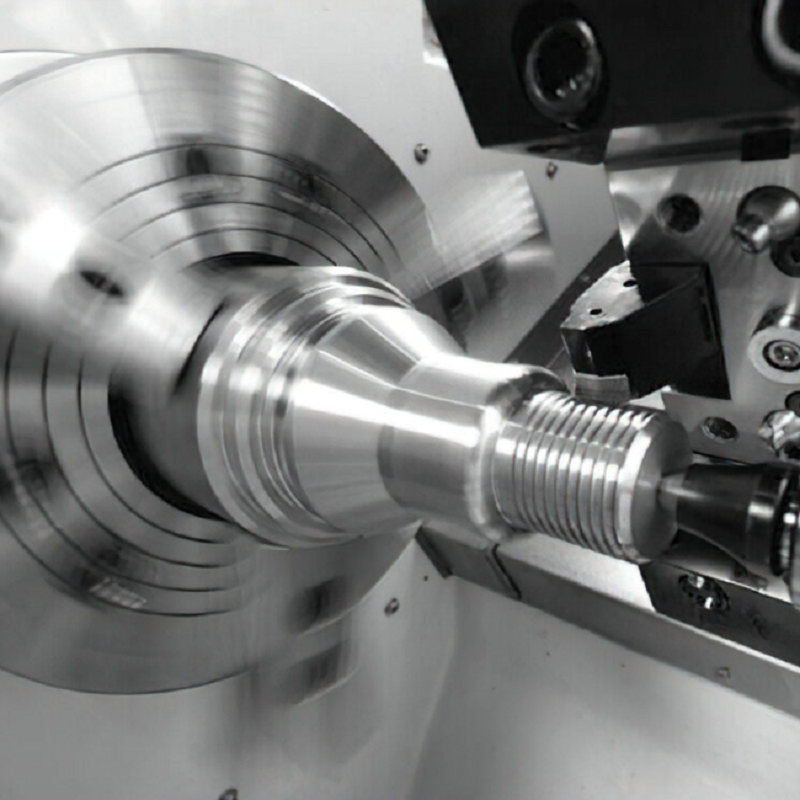

In the realm of Computer Numerical Control (CNC) machining, the design of cutting inserts plays a pivotal role in determining the efficiency, precision, and versatility of the machining process. CNC inserts, often made from carbide, ceramic, or other advanced materials, come in various shapes tailored to specific machining tasks and materials. Understanding the common shapes utilized in CNC insert...

Read more

Tungsten carbide has emerged as the material of choice for cutting tool inserts due to its exceptional hardness, strength, and wear resistance. This unique combination of properties makes tungsten carbide inserts highly desirable for a wide range of cutting and machining applications. In this article, we will discuss the various reasons why tungsten carbide is the preferred material for cutting to...

Read more

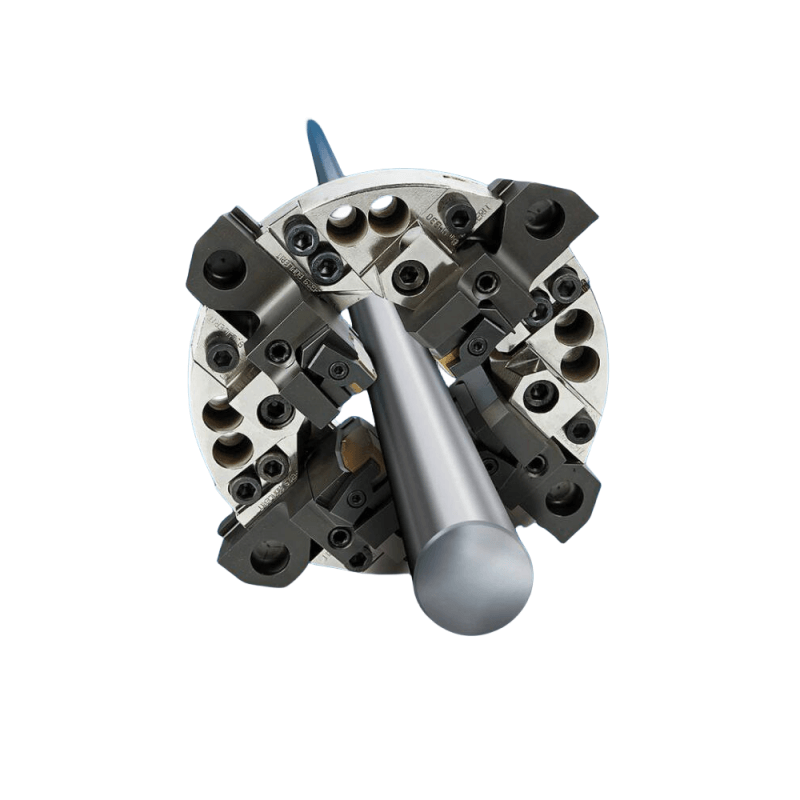

Bar peeling inserts play a crucial role in the metalworking industry, enabling efficient and high-quality machining operations. When selecting bar peeling inserts, it is essential to consider several key features that can significantly impact their performance and effectiveness. These features include material composition, coating, geometry, and overall durability....

Read more

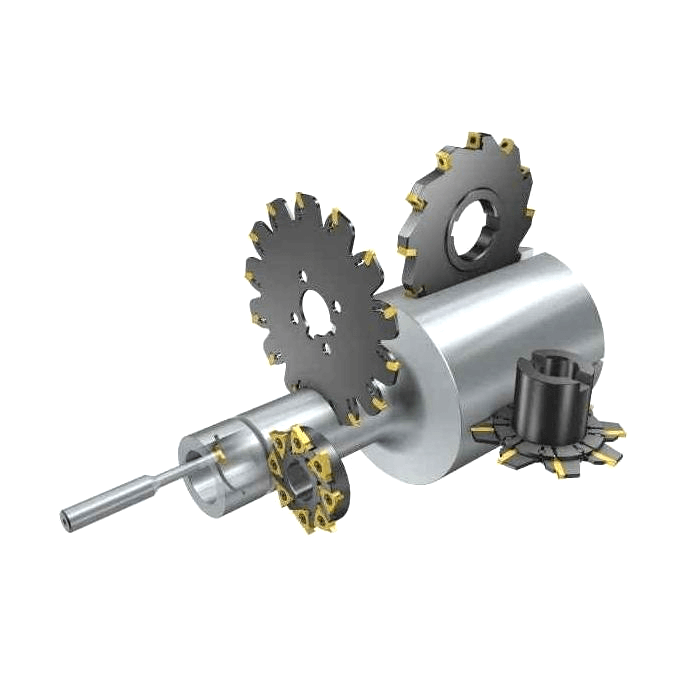

Slot milling cutters are essential tools used in the manufacturing industry for cutting and shaping materials. They are designed to create slots or grooves in workpieces, and they differ from other types of milling cutters in several key ways....

Read more

Choosing the correct coating for a carbide insert is a critical decision that directly impacts machining performance, tool life, and overall productivity. With a variety of coating options available, it is essential to consider several factors to ensure the optimal selection for specific machining applications....

Read moreContact person: Steve Lee

E-mail: [email protected]

Phone: 86-731-22200908

Address: Floor 4,Building NO.15,Zhichuang Plaza,NO.1299,Liyu Road,Tianyuan District,Zhuzhou City, Hunan, P.R. CHINA

Tel:0086-19973342799

E-mail: [email protected]

WeChat Official Account